20 years of expertise in formulating reliable 100% recycled resin

Manufacture your products with our recycled raw material, equivalent to virgin resin

Reduce your GHGs and become an active player in the circular economy

Exxel Polymers Produces Canada’s First Verra-Certified Plastic Credits

Exxel Polymers is proud to announce the successful production of Canada’s first Verra-certified plastic credits, under the Plastic Waste Reduction Standard (VCS Program).

With this certification, Exxel’s plastic credits provide companies and partners with a transparent, verified, and traceable way to offset their plastic footprint, while supporting the sustainable reduction of plastic pollution.

This historic milestone strengthens Exxel Polymers’ position as a Canadian leader in plastic recycling and circularity.

We are proud to contribute to a future where plastic is revalued, reused, and recycled, never wasted. For more details :

https://verra.org/programs/plastic-waste-reduction-standard/

Reducing

the environmental and ecological

impacts of plastics

Above all, we at Exxel Polymers Inc. are a recycler of plastic material recovered at the end of the industrial process and at the end-of-life cycle. We customize compounds for your production that have the mechanical properties and characteristics of virgin resin. From plastic waste, we produce a new, efficient, and, most importantly, 100% recycled raw material. The quality of the EXXEL resin is tested and certified. This quality allows optimal and high-performance large-scale production for parts or products containing recycled content.

16,5

millions

kilos

of plastic diverted from landfills

16,5

millions

kilos

of 100% recycled raw material

By reconditioning post-consumer (PCR) and pre-consumer (PRE) / post-industrial (PIR) plastics, we became an important strategic link in the plastic’s circular economy value chain. We can quantify and certify the PCR composition and provide a COA certification for each of our productions and formulations. When you need to overcome the most complex challenges, the Exxel Polymers Inc. team is your first line partner.

EXXEL meets your

performance and quality standards

POLYPROPYLENE

Impact resisting thermoplastic resin that is lighter, stiffer, and more versatile than PE. Odorless and food-safe material that is resistant to chemicals and moisture.

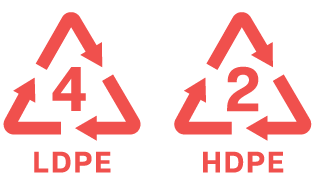

POLYETHYLENE

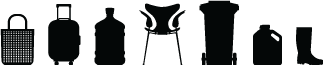

Greatly adaptable low-cost thermoplastic resin. Offered in several different categories depending on density in order to meet specific needs. Flexible and soft, LDPE notably makes up half of plastic packaging. HDPE is ductile and very resistant.

POLYSTYRENE

Expanded or extruded polystyrene resists shocks and compression. This non-toxic material is used for its insulating, waterproof and electrostatic properties. Stiffer and denser than PP, but less resilient.

Even before bringing our expertise and knowledge together in compounding and plastic recycling, our dearest wish was to found a working and living environment where we would have the pleasure of collaborating with a great team, each day, and be a part of a great common project. It is the combination of all the talents, know-how, and passion of our team and our partners that make EXXEL a caring and innovative company that continues to grow. The growing demand for recycled resin gives us the opportunity to expand the facility and the laboratory by 44,200 square feet. With the addition of advanced technologies and analytical instruments to test and certify the reliability of our resin, we aim to remain eco-responsible leaders and to actively contribute to reducing the environmental impact of end-of-life plastics.